Stepper Motor Basics: How to Calculate Step Angle and Speed?

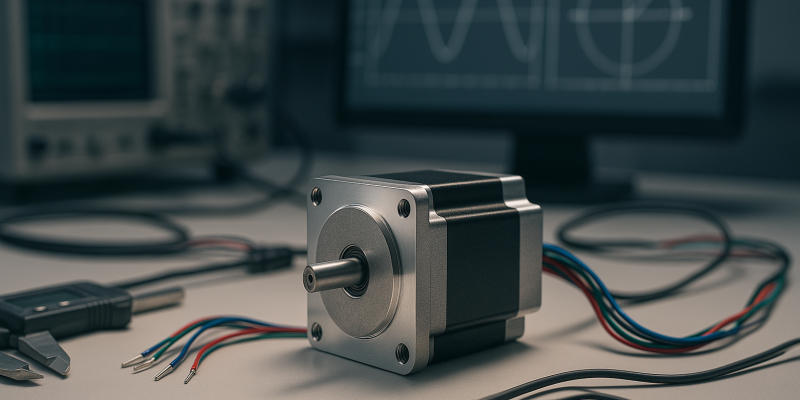

If you’re an enthusiast of robotics, 3D printing, or CNC machines, or even just like to tinker in your shed with projects encompassing technologies like these, the chances are that you will have come across stepper motors.

These clever little devices don’t spin continuously like a normal DC motor. Instead, they move in precise, fixed increments, or “steps”.

This makes them ideal for applications that need accurate positioning without expensive feedback sensors.

For many people who might be only just getting into stepper motors and the multitudes of ways they can be used, there are two questions they may be especially likely to seek answers for:

- How do I figure out the step angle?

- How fast can my stepper actually go?

In this article, then, we’ll take you through those answers. Along the way, we will touch on both manual calculation processes and the relevance of using trusted online tools to calculate step angle and speed quickly and accurately.

What Is Step Angle, And How Do You Calculate It?

The term “step angle” refers to the angle traversed by the motor in a single full step.

To put it another way, it is the number of degrees the motor shaft turns for each step (pulse) you send it.

The basic formula for figuring out the step angle is super straightforward. You take 360 degrees (°) and divide it by the number of steps per revolution.

Most common stepper motors that you can find from the best-known online sources such as RS and Amazon UK are 200 steps per revolution.

So, plugging this into the aforementioned formula would give you 360 / 200 = 1.8° per step.

This explains why you might have seen a lot of references online to “1.8° stepper”.

The fundamental step angle can be further reduced by using microstepping. This is a feature of modern motor drivers that divides each full step into small increments. As a result, smoother motion and higher resolution can be achieved.

How Can You Calculate a Stepper Motor’s Maximum Speed?

There isn’t a single “right” formula for determining a stepper motor’s maximum speed that accounts for all real-world variables.

However, one commonly cited theoretical formula for figuring out the quickest a stepper motor can go in revolutions per second (RPS), is: Max speed (RPS) = V / (L x 2 x Imax x spr).

In the above formula, V refers to applied voltage in volts, L refers to stepper motor inductance in henries, and Imax is the maximum or rated current per phase, in amperes. That leaves spr as meaning steps per revolution.

This formula is based on the time it takes for the current in the motor’s coils to ramp up sufficiently in each step. This is primarily limited by the motor’s inductance and the applied voltage.

Once you’ve come up with an RPS reading, you can easily convert to revolutions per minute (RPM) by multiplying by 60.

Why Might You Use an Online Calculator for Stepper Motor Calculations?

Projects involving the use of stepper motors can quickly become complex as other dynamic factors such as torque and acceleration need to be accounted for.

Fortunately, you can take much of the stress and time out of those essential calculations with the right online tool.

For example, you can head to the RS website and use the stepper motor calculator to determine speed, torque, and step angle.

At the very least, by keeping a reputable online stepper motor calculator bookmarked, you can have a convenient means of verifying the accuracy of your manual calculations.

By giving you instant results, such a calculator can help to save time in the design and troubleshooting process.

As a result, you will be well-placed to realise your project’s potential so much sooner.